10

2025

-

02

5052 Aluminum bar

The 5052 Aluminum Bar is a top-grade aluminum product known for its exceptional strength, corrosion resistance, and formability. This aluminum alloy, made with a combination of magnesium, is one of the most versatile materials available, ideal for a variety of applications across multiple industries.

5052 aluminum is Al-Mg alloy aluminum, magnesium is the main alloy element in 5052 alloy aluminum, is the most widely used one kind of rustproof aluminum, this alloy has high strength, especially the fatigue strength: High plasticity and corrosion resistance, heat treatment can not be strengthened, in the semi-cold hardening plasticity is good, cold hardening plasticity is low, good corrosion resistance, good weldability, poor cutting performance, polishing.Aluminum - magnesium alloys also contain small amounts of manganese, chromium, beryllium, titanium, etc. Except for a small amount of solid solution, most of the manganese in the alloy forms MnAl6. The role of chromium in 5052 aluminum plate is similar to that of manganese, which can improve the stress corrosion cracking ability, improve the strength of matrix metal and weld and reduce the tendency of welding crack, but its content is generally not more than 0.35%.

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

| Surface Treatment: | Polished |

| Technique: | Cold Drawn |

| Hardness: | standard |

| Al (Min): | 99% |

| Material: | Aluminun |

| Temper: | T3 - T8 |

| Tolerance: | ±1% |

| Sample: | Avaliable |

| Application: | construction |

| Shape: | Round |

| Yield (≥ MPa): | 90 |

| Ultimate Strength (≥ MPa): | 30 |

| Processing Service: | Cutting |

| Surface: | Polished |

| Length: | 1m-6m |

| Package: | Standard Seaworthy Package |

| Standard: | ASTM AISI JIS DIN GB |

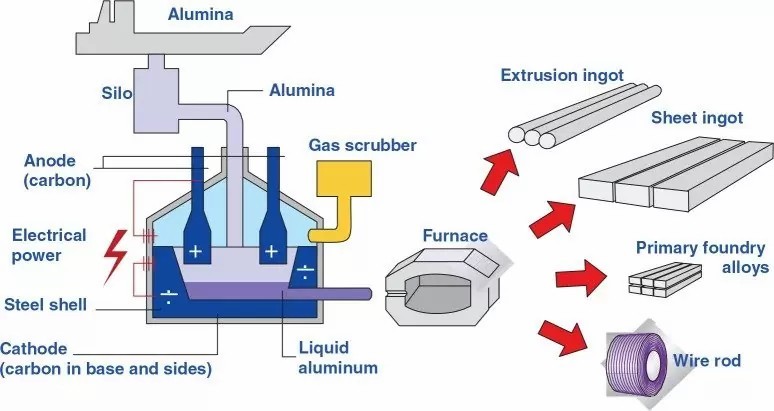

Aluminum Production Process

The 5052 Aluminum Bar is a top-grade aluminum product known for its exceptional strength, corrosion resistance, and formability. This aluminum alloy, made with a combination of magnesium, is one of the most versatile materials available, ideal for a variety of applications across multiple industries. From aerospace and automotive to marine and industrial applications, the 5052 Aluminum Bar offers reliable performance that meets the demanding requirements of both light and heavy-duty projects.

The alloy’s unique composition provides an excellent combination of strength and lightweight properties, making it perfect for use in structural and mechanical components where both attributes are essential. With high tensile strength and good fatigue resistance, the 5052 Aluminum Bar can handle both static and dynamic loads without deforming or cracking. Its strength-to-weight ratio makes it a favored choice for industries where reducing weight is critical without compromising on performance.

5052 Aluminum Bar is also highly resistant to wear and tear, and it retains its structural integrity even under repeated stress and movement. Its excellent weldability makes it ideal for custom fabrication, enabling it to be easily shaped and joined to form complex designs without losing its strength or performance. Whether used for frames, brackets, or protective casings, the 5052 aluminum bar proves itself to be a durable and cost-effective solution.

Available in a variety of sizes and configurations, the 5052 Aluminum Bar can be machined to meet specific project requirements, and its surface can be finished for additional protection. Anodizing or painting the bar enhances its ability to withstand wear, while also providing a visually appealing finish that can complement the overall design of the product.

In conclusion, the 5052 Aluminum Bar is an outstanding material that combines strength, corrosion resistance, and versatility. Whether used in aerospace, marine, industrial, or automotive applications, the 5052 Aluminum Bar offers exceptional durability and reliability. Its adaptability to various conditions, coupled with its ability to withstand tough environments, makes it a trusted solution for engineers, manufacturers, and designers.

5052 Aluminum bar

Next page

Other News