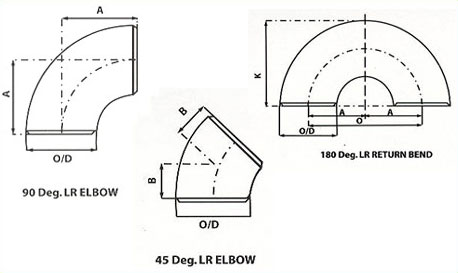

Steel Pipe Elbow

Classification :

Pipe fitting

PRODUCT DETAILS

Seamless Elbow Manufacturing Process (Heat Bending & Cold Bending)

One of the most common methods for manufacturing elbows is using hot mandrel bending from straight steel pipes. After heating the steel pipe at a elevated temperature, the pipe is pushed, expanded, bended by the inner tools of mandrel step by step. Applying hot mandrel bending can manufacture a wide size range seamless elbow. The characteristics of mandrel bending are strongely depend on the intergrated shape and dimensions of the mandrel. The using advantages of hot bending elbows include smaller thickness deviation and stronger bending radius than other bending methond type. Meanwhile, using bending instead of prefabricated bends substantially reduces the number of welds needed. This reduces the amount of work required and increases the quality and usability of pipes. However, cold bending is the process to bent the straight steel pipe at normal temperatures in a bending machine. Cold bending is suitable for pipes with an outer diameter of 17.0 to 219.1 mm, and wall thickness 2.0 to 28.0 mm. The recommended bending radius is 2.5 x Do. Normally at a bending radius of 40D. By using cold bending, we can get small radius elbows, but we need to pack the internals with sand to prevent wrinkling. Cold bending is a quick and inexpensive bending method. It is a competitive option for making pipelines and machine parts.

Welded Elbow Manufacturing Process (Small & Large)

Welded elbows are made from the steel plates, so it is not seamless steel elbows. Use a mould and press the steel plate to the shape of the elbow, then weld the seam to be a finish steel elbow. It is the old production method of the elbows. Recent years the small sizes elbows are almost manufactured from the steel pipes now. For the big size elbows, for example, it is very difficult to produce elbows over 36” OD from the steel pipes . So it is commonly made from the steel plates, pressing the plate to the shape of half elbow, and welding the two halves together. Since the elbows are welded in its body , the inspection of the welding joint is necessary . Commonly we use the X-Ray inspection as the NDT.

Packing and shipping

The company has domestic first-class professional technical consultants and a team of outstanding employees with professional skills. The main products are carbon steel/galvanized steel. Stainless steel/steel coil steel bars, galvalume, color-coated coils, profiles, steel bars, aluminum products, roof panels. Products are sold to more than 60 countries and regions in Europe, the Middle East, Southeast Asia, and Australia.

APPLICATION AREAS

We promise"complete specifications, prompt delivery, high quality, competitive price, "The unwavering supports you provide, along with the increasing requirements you put contributes to more varied high-quality products with more competitive prices we offer.Win-win situations are always our pursuit.

CUSTOMER VISIT

OUR ADVANTAGE

We have won recognition from our clients due to our good creditand good services.

Professional

Have perfect technical management and R&D process

Experience

Focus on the steel industry for many years

Quality

Product quality meets industry standards

Service

Our company has a professional service team

FAQ

Q:Do you accept the third party inspection?

Q: What ports of shipment are there?

Q: How many countries you already exported to?

Q:How about the delivery time?

Q:Does the product have quality inspection before loading?

Q:What product information do I need to provide?

RELATED PRODUCTS

GET A FREE QUOTE